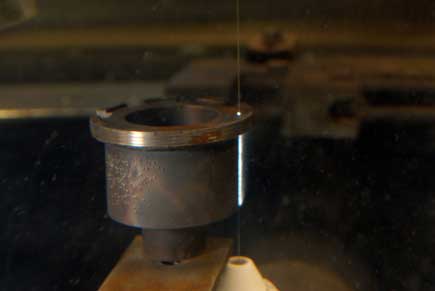

The machinery and punch press die manufacturing section

Equipment

The Mechanical Machinery Section directly depends on the Technical Office that receives the customer’s requests.

The feasibility study is followed by the design and manufacturing of punch press dies both for the hot chamber and for the cold chamber.

In addition to the manufacturing of new products, the Section also manages the ordinary and extraordinary maintenance of all equipment used in the production sections, by maintain them efficient so that the best quality of the product is obtained.

In detail, the outfit is as follows.

Design:

- CAD 3D Catia Pro Engineering Inventor station

- CAM 3D Sum station

Work centers:

- High-speed Huron KX8 CNC Siemens work center

- Vertical Yamazaki Mazak Mod. VTC 200B CNC Mazatrol 640 M work center

- Vertical Famup MCX600 CNC Fanuc 21I work center

- 02 Fanuc Robodrill EL/FL a 4 axe CNC Fanuc31i work centers

- Horizontal Yamazaki Mazak A2 pallets 400×400 Mod. H415 CNC –Plus work center

CNC lathes

- Biglia 501 CNC Fanuc 18I lathe

- No.2 Takisawa EX108 CNC Fanuc 21I lathes

- Daewoo Puma 240Mb CNC Fanuc OIT lathe

Electrical discharge machining

- Electrical discharge machining with momentum CNC ONA Mod. DB300

- Electrical discharge machining with momentum ONA Compact

- Wired electrical discharge machining with momentum ONA AE300

Grinding

- Tangential grinding Jung 600×300

- Tangential grinding 1000×400

- Inner-outer Tripet grinding

Traditional machines

- No. 2 parallel lathe

- No. 3 universal milling machine

- Radial and column drill

- Tool and cutter grinders

- TIG welding machines

- Threader

- Saws

- Pantograph

Measuring instruments

- DEA coordinate measuring machine

- Galileo hardness tester

- Elbo Controlli tool presetters

- Digital Mitutoyo surface roughness tester

- Bore gauges

- Series of micrometers

- Buffers and blocks